A Widescreen Blender-Style Interface

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

15 Jun 2018 23:35 - 15 Jun 2018 23:44 #112445

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

Last edit: 15 Jun 2018 23:44 by BrendaEM.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

15 Jun 2018 23:42 #112448

by andypugh

Replied by andypugh on topic A Widescreen Blender-Style Interface

Maybe I haven't made it clear that I support the idea of a well thought out, attractive user interface. A common complaint from Mach3 users is that LinuxCNC looks bad, or has no "skins" or whatever. It would be nice to be able to refute that.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

15 Jun 2018 23:44 - 15 Jun 2018 23:51 #112449

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

That's why we are here : )

Well, I wanted to give something back, too.

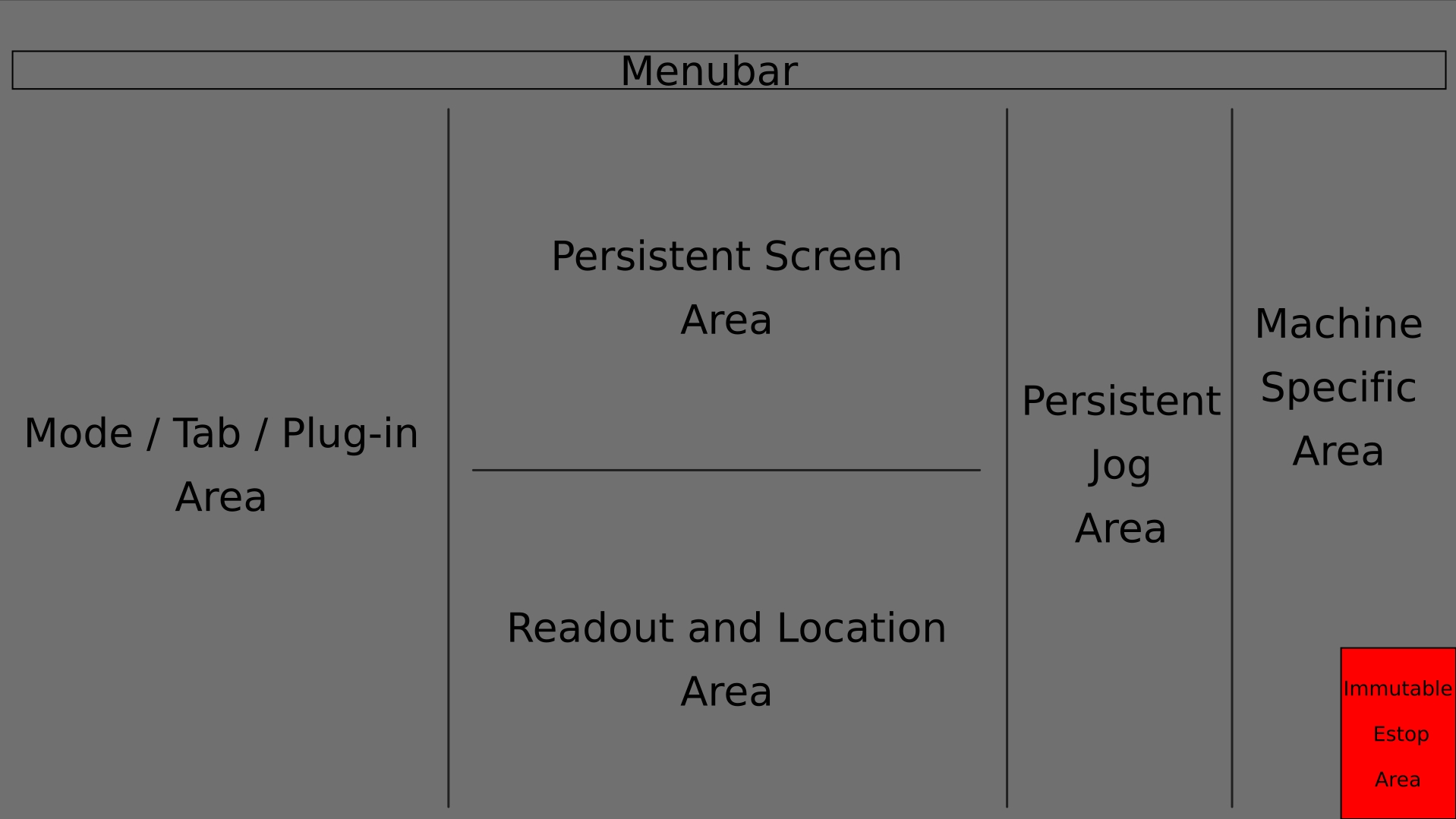

Though, as I have stated, all the present interfaces have good ideas...that I am trying to rip off equally. The big Estop idea came from the Craftsman interface, but it was changed to be on the right because most people are right-handed. Left-hander's are quicker than we are, so they can make up the difference : )

There's even a little bit of a newspaper strip layout in there, too.

Well, I wanted to give something back, too.

Though, as I have stated, all the present interfaces have good ideas...that I am trying to rip off equally. The big Estop idea came from the Craftsman interface, but it was changed to be on the right because most people are right-handed. Left-hander's are quicker than we are, so they can make up the difference : )

There's even a little bit of a newspaper strip layout in there, too.

Last edit: 15 Jun 2018 23:51 by BrendaEM.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11625

- Thank you received: 3913

16 Jun 2018 01:15 #112453

by rodw

If I had more room, I'd have 2!

Replied by rodw on topic A Widescreen Blender-Style Interface

Love your work AndyEveryone needs a lathe, but most don't realise it

If I had more room, I'd have 2!

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

19 Jun 2018 11:39 #112576

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

Please Log in or Create an account to join the conversation.

- Sparky961

-

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 15

19 Jun 2018 12:33 #112578

by Sparky961

Replied by Sparky961 on topic A Widescreen Blender-Style Interface

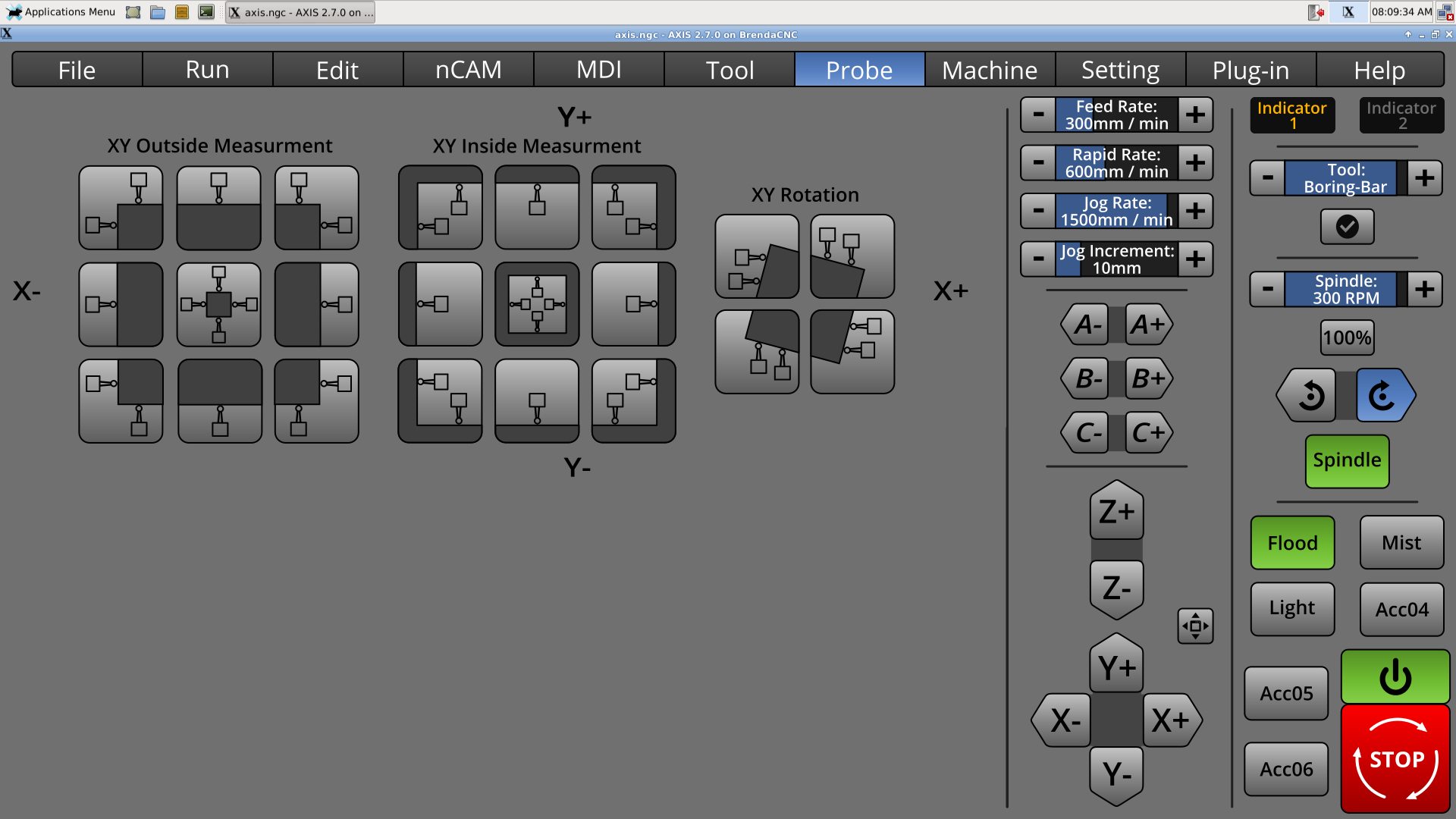

It occurred to me after looking at your more recent screenshots that the DRO elements don't need to have near as many significant digits. Most commercial mills and lathes I've seen don't go beyond 0.0001", and I'd bet that even the best grinders and EDM machines don't need any more than 6 significant digits.

I suspect the space that's saved could be used more efficiently.

I suspect the space that's saved could be used more efficiently.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

19 Jun 2018 16:03 #112587

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

When I started, I just went for a 10-digit mantissa.

Because the area immediately to the right of the displays are populated with some of the most-used buttons, they are large. And because they are large, it would take the loss of perhaps 4-5 digits to return add another row of buttons.

Ideally, you are likely right, though.

Because the area immediately to the right of the displays are populated with some of the most-used buttons, they are large. And because they are large, it would take the loss of perhaps 4-5 digits to return add another row of buttons.

Ideally, you are likely right, though.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

19 Jun 2018 16:10 #112588

by andypugh

Replied by andypugh on topic A Widescreen Blender-Style Interface

As a sanity check:

The coefficient of thermal expansion of aluminium is 23^-6 / K

A 10mm (very small) part will expand 0.0002mm for a 1 degree change in part temperature.

4 decimal places for a metric layout and 6(maybe 5) on imperial covers pretty much any part that it is possible to manufacture. On a real machine the extra digits are just visual noise.

The coefficient of thermal expansion of aluminium is 23^-6 / K

A 10mm (very small) part will expand 0.0002mm for a 1 degree change in part temperature.

4 decimal places for a metric layout and 6(maybe 5) on imperial covers pretty much any part that it is possible to manufacture. On a real machine the extra digits are just visual noise.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

19 Jun 2018 16:19 #112589

by andypugh

Replied by andypugh on topic A Widescreen Blender-Style Interface

Or to look at it another way: How many digits are on the digital micrometer that you will inspect the parts with?

I have managed to find one micrometer with 6 digits in imperial:

ecatalog.mitutoyo.com/MDH-Micrometer-Hig...icrometer-C1816.aspx

Most have only 5.

I have managed to find one micrometer with 6 digits in imperial:

ecatalog.mitutoyo.com/MDH-Micrometer-Hig...icrometer-C1816.aspx

Most have only 5.

Please Log in or Create an account to join the conversation.

- Sparky961

-

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 15

19 Jun 2018 16:41 #112591

by Sparky961

And often that last digit is a "0" or a "5".

Thanks for adding context to my comment. As a programmer, give me as many bits as you can spare. As a machinist, you were spot on when you call the extra numbers "noise".

Getting into the "tenths" range of measurements (0.0001" or approx. 0.003mm) and achieving repeatable results requires an incredibly clean environment, high quality (expensive) tools, and temperature/process controls.

Replied by Sparky961 on topic A Widescreen Blender-Style Interface

Most have only 5.

And often that last digit is a "0" or a "5".

Thanks for adding context to my comment. As a programmer, give me as many bits as you can spare. As a machinist, you were spot on when you call the extra numbers "noise".

Getting into the "tenths" range of measurements (0.0001" or approx. 0.003mm) and achieving repeatable results requires an incredibly clean environment, high quality (expensive) tools, and temperature/process controls.

Please Log in or Create an account to join the conversation.

Time to create page: 0.838 seconds