"Origami" CNC Plasma Build - folding 1200 x 600mm cut area

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

06 Apr 2021 21:54 #205194

by Joco

Have read about them on a few commercial sites I can see there is quite a divided opinion with no real clear winner. However I think your last comment does hit the nail on the head "so much easier". This is my first plasma build I'm already biting off a bit. So tending to head down the well trodden path of those who have gone before AND trying to keep things simple(ish).

So will stick with the fold/pivot idea for this build. Take the compromises that come with that, build a water table for it with an ability to fill/empty from a small "drum" under low psi. Heck that could even be controlled via lcnc. With the 7i76e I am going to be spoiled for IO pins.

Will try and refine my existing table design a bit. It feels a bit like tank engineering at the moment.

Rod - is there is reasonably basic math or online calcs to determine how much base width I need on the wheels for stability when table is vertical? Trying to work out how narrow a base I can get away with. I can always add some outrigger support when the table is flat for cutting.

Get it all working and then see where things stand. As tommylight has said - just get some steel and stick it together, get things moving and learn.

Cheers - J.

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

... I always wanted the spaceship to be a 2 zone downdraft using one of the fans I shared with you but in the end, creating a water tray was so much easier.

Have read about them on a few commercial sites I can see there is quite a divided opinion with no real clear winner. However I think your last comment does hit the nail on the head "so much easier". This is my first plasma build I'm already biting off a bit. So tending to head down the well trodden path of those who have gone before AND trying to keep things simple(ish).

So will stick with the fold/pivot idea for this build. Take the compromises that come with that, build a water table for it with an ability to fill/empty from a small "drum" under low psi. Heck that could even be controlled via lcnc. With the 7i76e I am going to be spoiled for IO pins.

Will try and refine my existing table design a bit. It feels a bit like tank engineering at the moment.

Rod - is there is reasonably basic math or online calcs to determine how much base width I need on the wheels for stability when table is vertical? Trying to work out how narrow a base I can get away with. I can always add some outrigger support when the table is flat for cutting.

Get it all working and then see where things stand. As tommylight has said - just get some steel and stick it together, get things moving and learn.

Cheers - J.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

11 Apr 2021 22:01 - 11 Apr 2021 22:52 #205681

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Well I have been working away on plans and started cutting metal and beginning to weld things together. Along with making mistakes and having to unweld things - that is another story with some supporting language that really isn't printable.

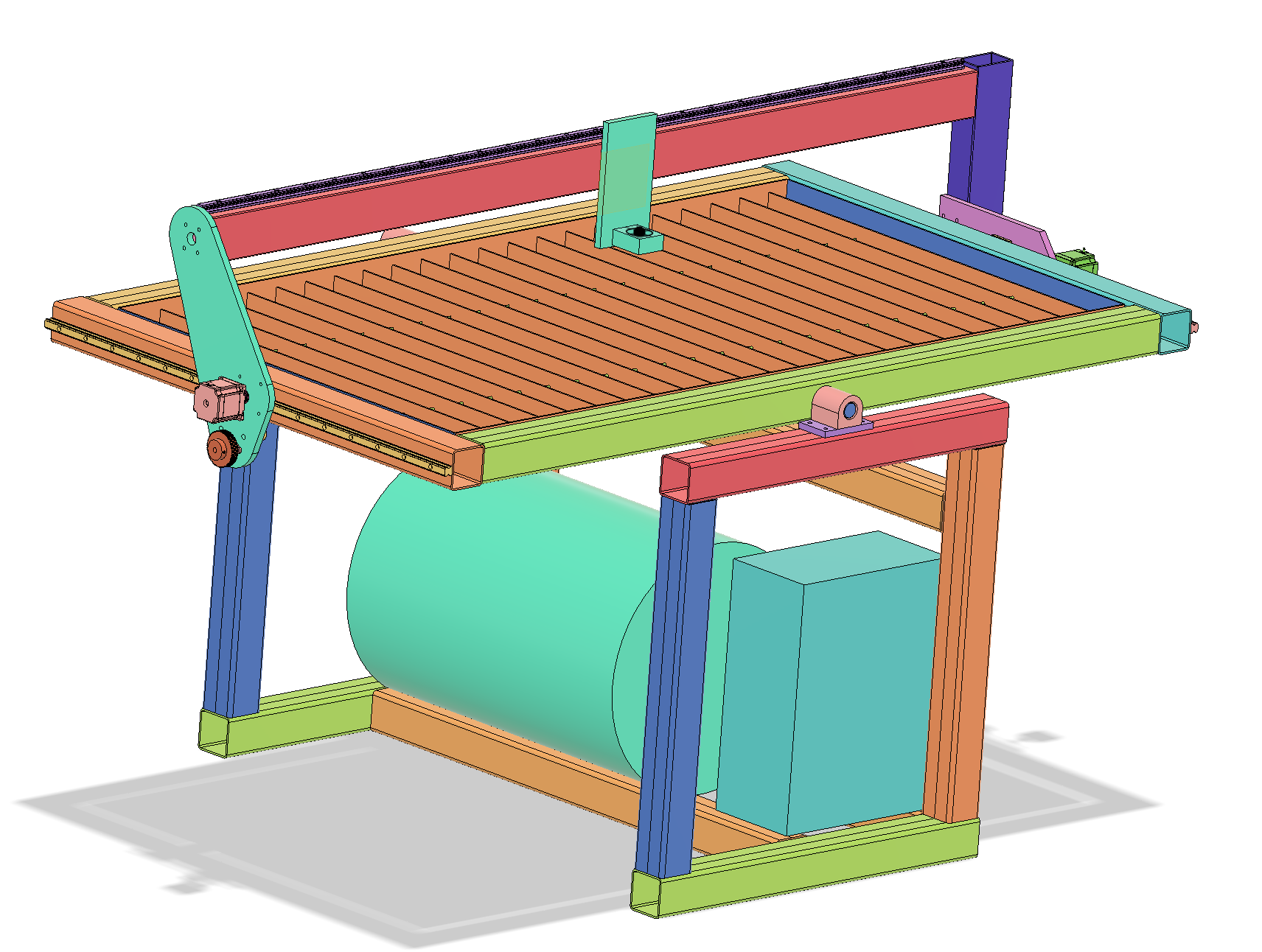

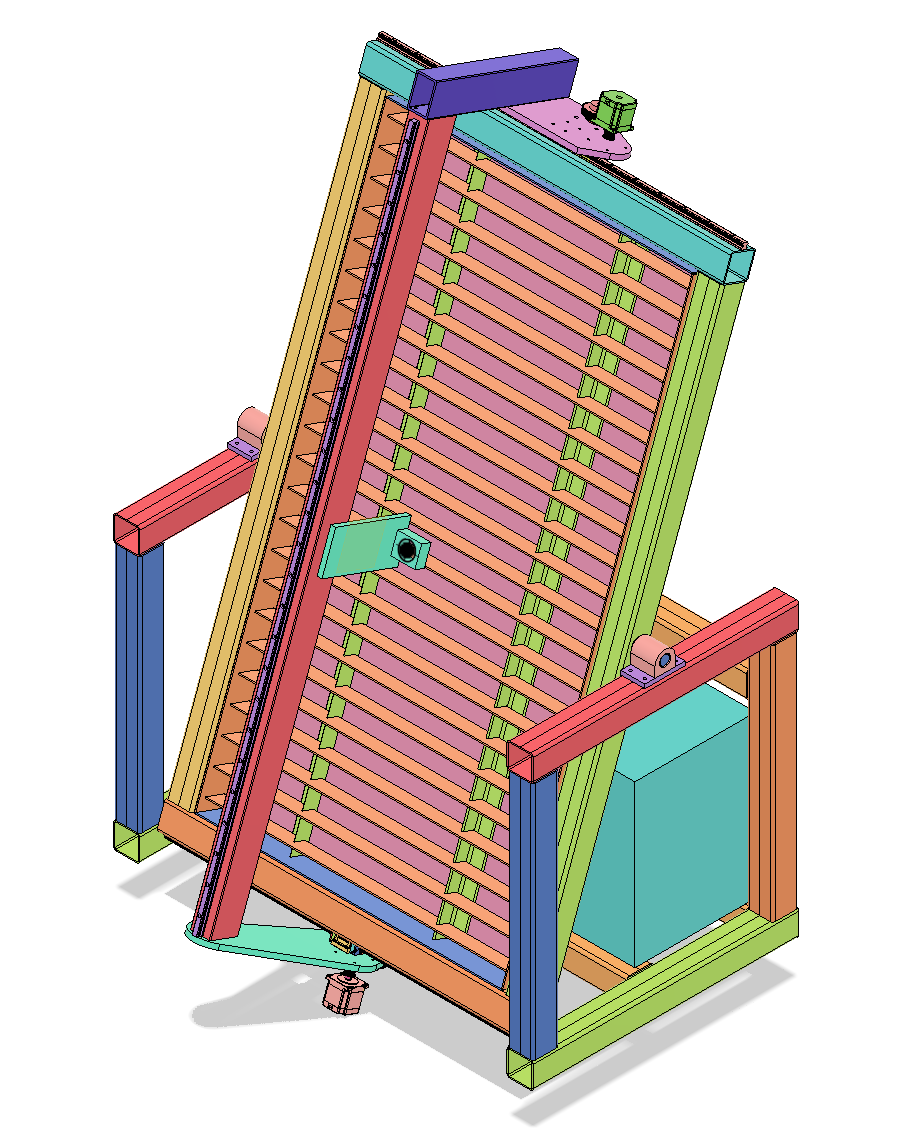

Anyway attached are some cad screen shots of the design. This is the overall table. It's not complete as yet but the key features are in place and checked so that I can start construction of the frames.

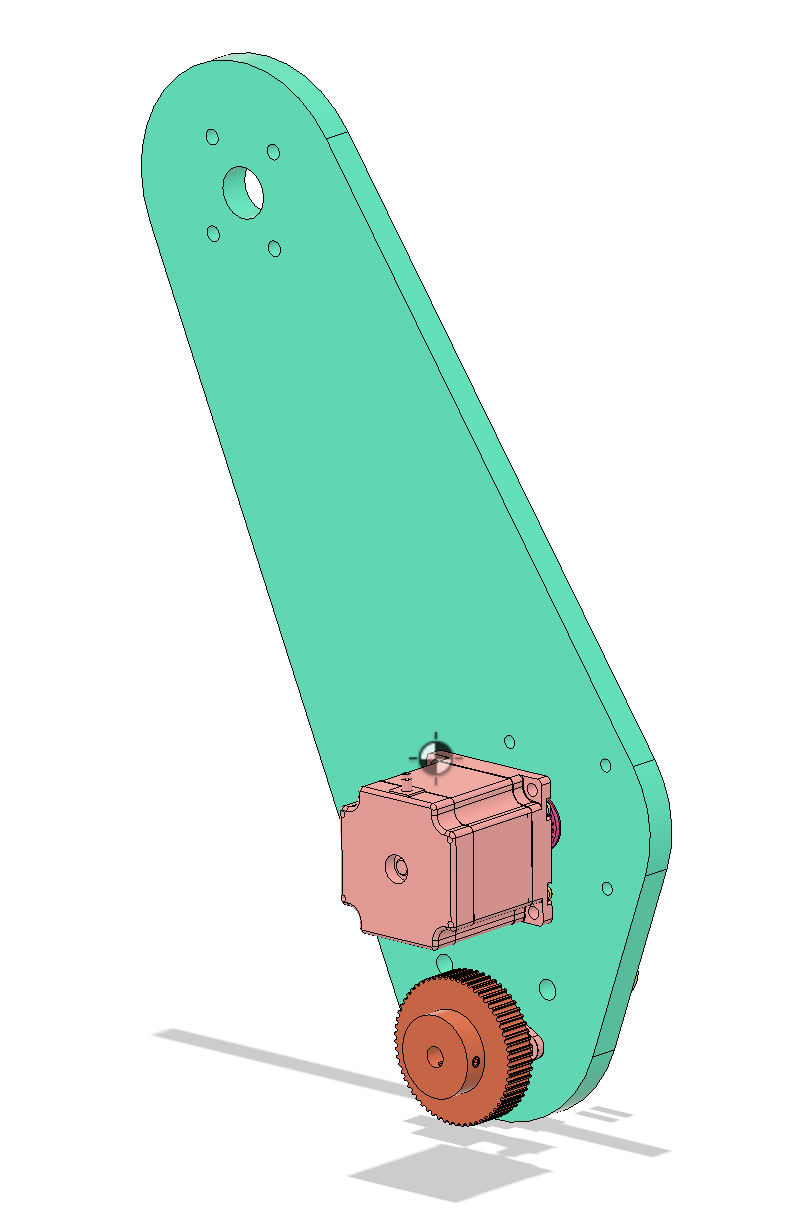

I have two potential gantry side supports that I am debating with myself over. The more elegant one made from a single 12mm piece will be a little more challenging to make given the size of it. I think I can just fit it on my small cnc mill. Or will have to do "old school" on the big manual mill.

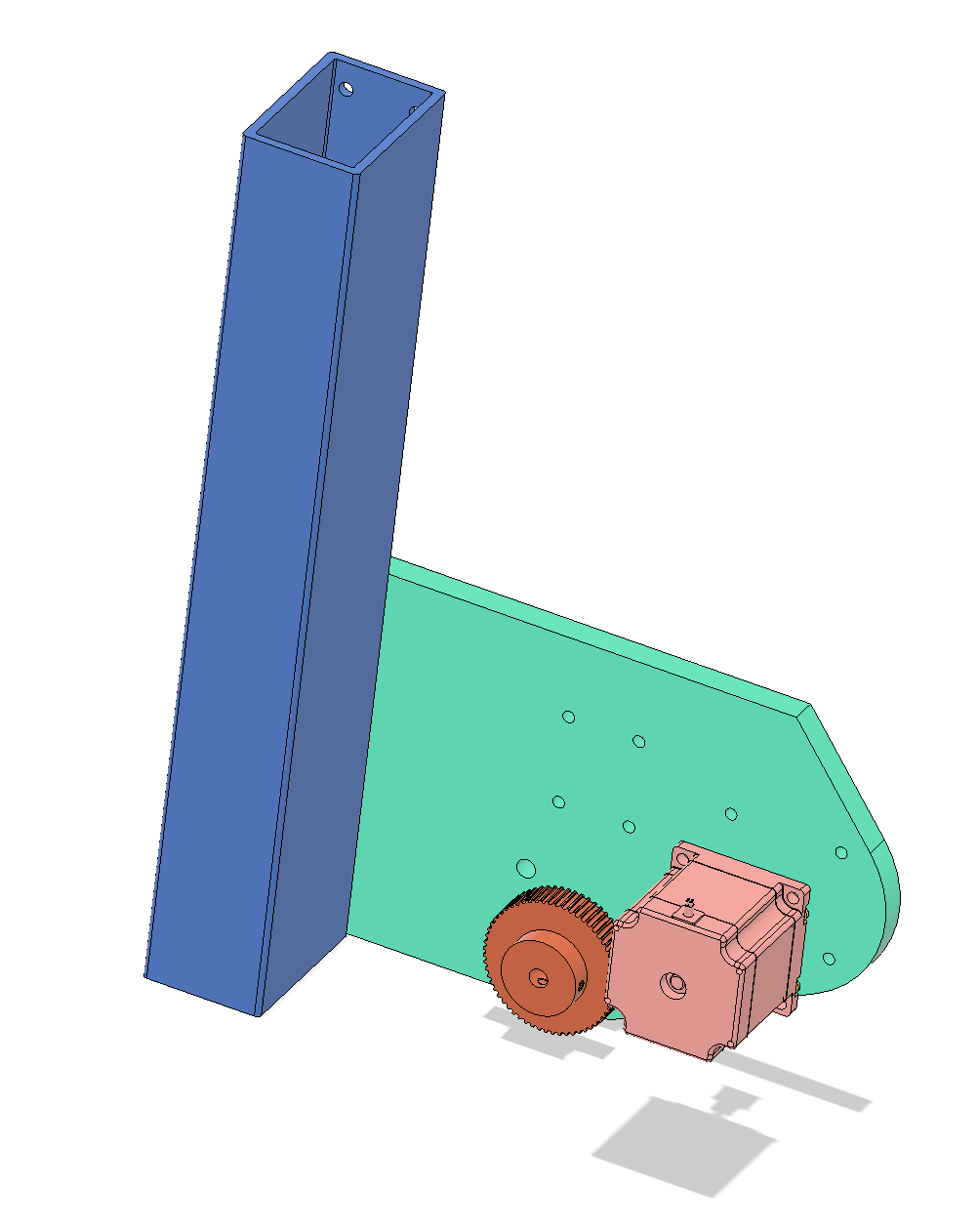

The second option is two piece construction. A 12mm part screwed to a piece of 75x50x4mm RHS (the same as used on the gantry span). Given the sizes I can easily do the 12mm flat on the cnc mill.

I think they will both do the same job but one clearly looks a lot more elegant than the other. However if there are advantages from an structural or adjustability angle between them that I am not aware of then keen for views.

Or of someone has a better design they can point me to? That also would be valuable.

Cheers - J.

Anyway attached are some cad screen shots of the design. This is the overall table. It's not complete as yet but the key features are in place and checked so that I can start construction of the frames.

I have two potential gantry side supports that I am debating with myself over. The more elegant one made from a single 12mm piece will be a little more challenging to make given the size of it. I think I can just fit it on my small cnc mill. Or will have to do "old school" on the big manual mill.

The second option is two piece construction. A 12mm part screwed to a piece of 75x50x4mm RHS (the same as used on the gantry span). Given the sizes I can easily do the 12mm flat on the cnc mill.

I think they will both do the same job but one clearly looks a lot more elegant than the other. However if there are advantages from an structural or adjustability angle between them that I am not aware of then keen for views.

Or of someone has a better design they can point me to? That also would be valuable.

Cheers - J.

Attachments:

Last edit: 11 Apr 2021 22:52 by Joco.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11625

- Thank you received: 3913

12 Apr 2021 00:27 #205688

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

For a part like that gantry end, I would just get it laser cut and tap any holes when the part comes back (What I did for the Spaceship!) They should be able to cut tap ready holes for M6. Smaller than that, they can etch the position and you need to drill.

I think the green part is the way to go.

I think the green part is the way to go.

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

12 Apr 2021 22:02 #205739

by andypugh

Replied by andypugh on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Would the motor be safer from damage on the other side of the uprights? (well, damage from the floor, or items on the floor) it is more likely to be damaged by the work or the plasma.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

12 Apr 2021 22:33 #205746

by Joco

It's a good question Andy and one I flip-flopped on quite a bit. I settle on having the motors on the outside so as to keep them away from any crap being spat out buy the torch. The intention is to create sheet metal or high impact plastic covers over those ends to protect that assembly from being knocked and general air borne grimme. This external model along with protective covers is a pattern I have seen used elsewhere. For some reason I think tommylight has done something along these lines.

As a further "protection" when the machine is in its stored state there will be a piece of equipment (on wheels) sitting in front of it that will act as a buffer for that gantry end assembly from it getting accidentally knocked. But with this style of machine where I can't put it fully vertical there is always some risks involved. However ... I have worked out that if I fabricated a custom water chamber I could make a shape that could get the volume needed while allowing the table to tilt to the vertical another 5-10 degrees. That small amount will bring things that much further into the bounds of the frame and further reduce the risk of things getting knocked. It might mean I need to add some extra spacing to the wheels I have. They have a finished working height of 130mm.

Cheers - J.

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Would the motor be safer from damage on the other side of the uprights? (well, damage from the floor, or items on the floor) it is more likely to be damaged by the work or the plasma.

It's a good question Andy and one I flip-flopped on quite a bit. I settle on having the motors on the outside so as to keep them away from any crap being spat out buy the torch. The intention is to create sheet metal or high impact plastic covers over those ends to protect that assembly from being knocked and general air borne grimme. This external model along with protective covers is a pattern I have seen used elsewhere. For some reason I think tommylight has done something along these lines.

As a further "protection" when the machine is in its stored state there will be a piece of equipment (on wheels) sitting in front of it that will act as a buffer for that gantry end assembly from it getting accidentally knocked. But with this style of machine where I can't put it fully vertical there is always some risks involved. However ... I have worked out that if I fabricated a custom water chamber I could make a shape that could get the volume needed while allowing the table to tilt to the vertical another 5-10 degrees. That small amount will bring things that much further into the bounds of the frame and further reduce the risk of things getting knocked. It might mean I need to add some extra spacing to the wheels I have. They have a finished working height of 130mm.

Cheers - J.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

12 Apr 2021 22:43 - 12 Apr 2021 22:44 #205747

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

A few questions if I may ...

Rod - I have been reading through your spaceship build and maybe I am missing it but roughly what is the gap from bed top to the bottom of your gantry? 150mm, 200mm, 300mm more? I'm trying to get a feel for what would be reasonable v's excessive v's under baked.

Everyone with Mesa experience:

(a) I will be using a 7i76e card. I already have a machine with linuxcnc all installed and tuned setup with a PCI plug-n-go setup and 1080p touch screen. I am wondering if I can make it do double duty? i.e. have a config that runs the mill and a different config that uses the onboard NIC to run the plasma. I already have a USB wifi dongle on it so can get the network separation.

(b) Looking at the portability side of things a laptop with its combined screen/compute would be an ideal way to connect to and drive the 7i76e. Is there any laptop options that when turned into "performance mode" will be effective? Or am I asking for a unicorn?

Thanks everyone.

Rod - I have been reading through your spaceship build and maybe I am missing it but roughly what is the gap from bed top to the bottom of your gantry? 150mm, 200mm, 300mm more? I'm trying to get a feel for what would be reasonable v's excessive v's under baked.

Everyone with Mesa experience:

(a) I will be using a 7i76e card. I already have a machine with linuxcnc all installed and tuned setup with a PCI plug-n-go setup and 1080p touch screen. I am wondering if I can make it do double duty? i.e. have a config that runs the mill and a different config that uses the onboard NIC to run the plasma. I already have a USB wifi dongle on it so can get the network separation.

(b) Looking at the portability side of things a laptop with its combined screen/compute would be an ideal way to connect to and drive the 7i76e. Is there any laptop options that when turned into "performance mode" will be effective? Or am I asking for a unicorn?

Thanks everyone.

Last edit: 12 Apr 2021 22:44 by Joco.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7231

13 Apr 2021 00:25 #205751

by tommylight

For a water table at least 200mm, 300 should be max.

Yes, but not at the same time.

Some new-ish Fujitsu will do just fine, but i have no model number.

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

A few questions if I may ...

Rod - I have been reading through your spaceship build and maybe I am missing it but roughly what is the gap from bed top to the bottom of your gantry? 150mm, 200mm, 300mm more? I'm trying to get a feel for what would be reasonable v's excessive v's under baked.

For a water table at least 200mm, 300 should be max.

Everyone with Mesa experience:

(a) I will be using a 7i76e card. I already have a machine with linuxcnc all installed and tuned setup with a PCI plug-n-go setup and 1080p touch screen. I am wondering if I can make it do double duty? i.e. have a config that runs the mill and a different config that uses the onboard NIC to run the plasma. I already have a USB wifi dongle on it so can get the network separation.

Yes, but not at the same time.

(b) Looking at the portability side of things a laptop with its combined screen/compute would be an ideal way to connect to and drive the 7i76e. Is there any laptop options that when turned into "performance mode" will be effective? Or am I asking for a unicorn?

Some new-ish Fujitsu will do just fine, but i have no model number.

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

13 Apr 2021 02:32 #205759

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Thanks Tommy. I have remodelled to accomodate 200mm height. I have also done some adjusting to see what I can do to be able to store the table fully vertical. If I do that then with a 200mm gantry (table top to bottom of gantry) eveything JUST fits inside the boundary of the frame. Assuming I park the X axis at the top so torch and cables are out of the way. While not necessary it minimises the footprint to be just the base size (approx 660mm x 1040mm). It does create some other challenges but what the heck, where would life be without some challenges.

On the ethernet front, yup undersatnd one at a time. And for my shop that is just fine. I do have spare Core2 machines that have good latency so its not like I have to do it. Just good to know it is an option.

I have a few spare laptops I might check just for a chuckle. But it was really a bit of a wish. Not seen any of fujitsu machines in the local market. All Dell, Lenovo, HP.

Cheers - J.

On the ethernet front, yup undersatnd one at a time. And for my shop that is just fine. I do have spare Core2 machines that have good latency so its not like I have to do it. Just good to know it is an option.

I have a few spare laptops I might check just for a chuckle. But it was really a bit of a wish. Not seen any of fujitsu machines in the local market. All Dell, Lenovo, HP.

Cheers - J.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11625

- Thank you received: 3913

13 Apr 2021 12:17 #205777

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

I've got about 86mm of travel on the Z.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

13 Apr 2021 18:46 #205815

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Tommy - re your 200-300mm clearance from table top to bottom of gantry. Could you expand on why this is the target? Not debating it just keen to learn what drives that size band.

Rod - with your travel on Z is the torch tip always sitting below the gantry spans lower edge? From pics I recall seeing I was sure there was a reasonable space under it all.

Rod - with your travel on Z is the torch tip always sitting below the gantry spans lower edge? From pics I recall seeing I was sure there was a reasonable space under it all.

Please Log in or Create an account to join the conversation.

Time to create page: 0.314 seconds