"Origami" CNC Plasma Build - folding 1200 x 600mm cut area

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

19 Jul 2021 23:13 - 19 Jul 2021 23:22 #215353

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Thanks. 2mm lead will be easier on the motor from a load/torque perspective but might be an issue in that to get the level of travel needed to respond to changes in height as things move the motor might not be able to spin fast enough?

The other challenge will be finding a 4mm lead locally. I want to buy NZ but I keep havingo to go offshore cose no one local seems to have stuff. Or if they do they are charging 300-400% more than I can source it for offshore.

update: All motors runnig off 48V supply.

Cheers - J.

The other challenge will be finding a 4mm lead locally. I want to buy NZ but I keep havingo to go offshore cose no one local seems to have stuff. Or if they do they are charging 300-400% more than I can source it for offshore.

update: All motors runnig off 48V supply.

Cheers - J.

Last edit: 19 Jul 2021 23:22 by Joco.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

19 Jul 2021 23:40 #215354

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Yeah that should be more than enough voltage to drive the motors quite fast, so even 2mm should do just fine.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

20 Jul 2021 00:06 #215355

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Thanks for the advice Tommy. I'll run with 2mm lead as I can find the locally easily (as I can with 8mm lead). I would hope that I am not dealing with so much warpage that I need to move multiple mm's in sub second intervals. Worse case will be I "live and learn" and move to 4mm lead later after I import the needed parts.

Cheers - J.

Cheers - J.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

21 Jul 2021 06:07 #215459

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

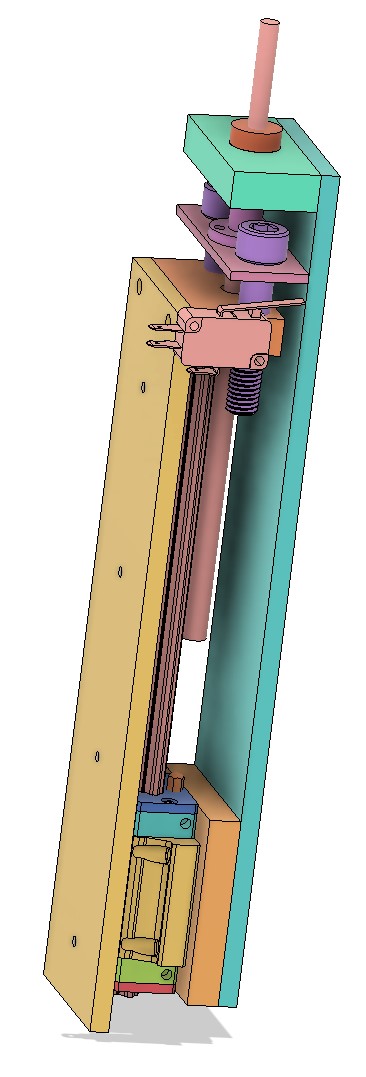

Taking on Tommy's advice and inspiration from his Z design I have been redisgining the Z assembly. This design is 46mm from front to back.It has 130mm of travel and the total height of of the backplate is 270mm. Amount of travel on the float switch is probaly around 8mm at the point of trigger. Total physical travel is 13mm.

Interested in views, improvements or potential gotchas.

Cheers - James.

Interested in views, improvements or potential gotchas.

Cheers - James.

Attachments:

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

21 Jul 2021 09:00 #215465

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Looks good. The only thing to watch is to be able to adjust the float switch hysteresis but I guess you can adjust that with the bolts.

I added an adjustment screw so the float switch just moved the minimum amount to trigger for speed.

I added an adjustment screw so the float switch just moved the minimum amount to trigger for speed.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

21 Jul 2021 09:08 #215469

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Make the switch location so that the plate triggering it rests on the supporting plate when pressed down, not on the switch.

Saves some switches!

Saves some switches!

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

21 Jul 2021 09:14 #215470

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Also, I learnt the hard way, the switch should be on the fixed part, not the moving part so the wires are not flexing all the time...

Try and design it so the switch body is safely out of the way so it can't be smashed...

Try and design it so the switch body is safely out of the way so it can't be smashed...

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

21 Jul 2021 10:00 #215474

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Rod - with this design I'm not too sure how I can avoid a flexing wire situation. Definately need to get the switch into a safe spot. But all good refinements to look at after this first cut.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

21 Jul 2021 10:08 #215476

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

If the part the acme screw nut is bolted to was a piece of angle iron, it would be an ideal spot for a switch with minimal wire flex...

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

22 Jul 2021 08:05 - 22 Jul 2021 08:06 #215555

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

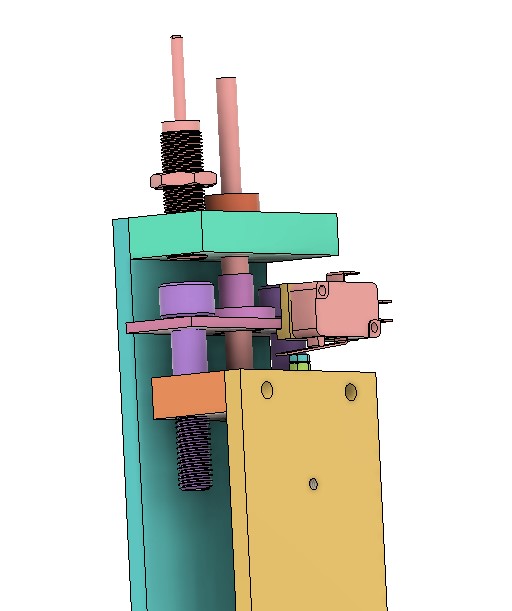

Attachments:

Last edit: 22 Jul 2021 08:06 by Joco.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.158 seconds