"Origami" CNC Plasma Build - folding 1200 x 600mm cut area

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

04 Sep 2021 23:37 - 04 Sep 2021 23:38 #219638

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Yeah horrible black dust. Hopefully the water table would keep that to a minimum. I'm thinking about options to cover the ends. I can 3d print some plastic plugs for the mounting holes that I made for the CNC work. Then either a plastic or sheet metal/aluminium to keep the motors and pulleys more clean.

Oh and soved the stuck beaing alignment issue. A little bit of 3-in-one oil and some leverage. Some of these were not too bad others were so solid I thought I was going to bend the bar before they clicked loose.

Oh and soved the stuck beaing alignment issue. A little bit of 3-in-one oil and some leverage. Some of these were not too bad others were so solid I thought I was going to bend the bar before they clicked loose.

Last edit: 04 Sep 2021 23:38 by Joco.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

04 Sep 2021 23:55 #219641

by rodw

Replied by rodw on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Yes, you quickly forget how clean they are at the start of their life!Very nice, indeed !

Soon all that will be covered in black dust !

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

12 Sep 2021 07:40 #220280

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

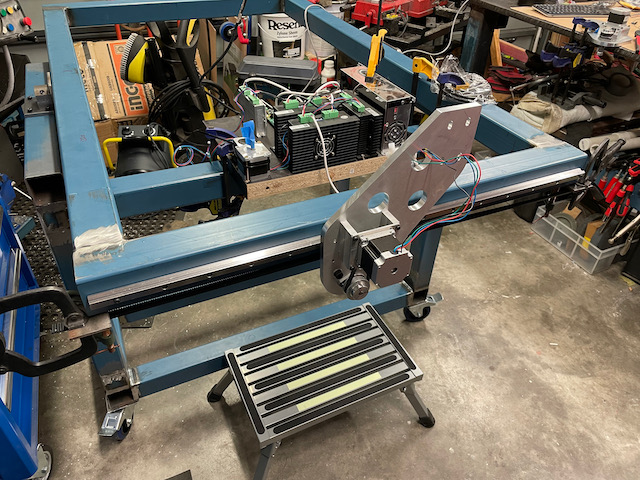

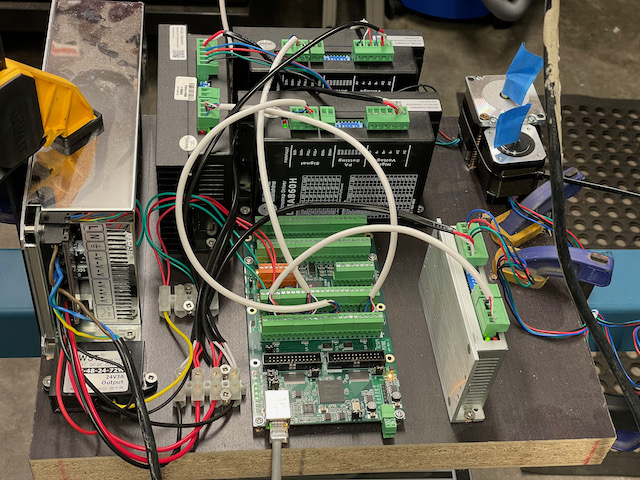

This is a bit hacky but heck if don't care, its first real world movement. Seriously ... FIRST MOVEMENT. Yeah I know, nothing new for many here but I'm stocked. It's always so cool with a bunch of design and thinking and advise taking and machining actually has a good result.

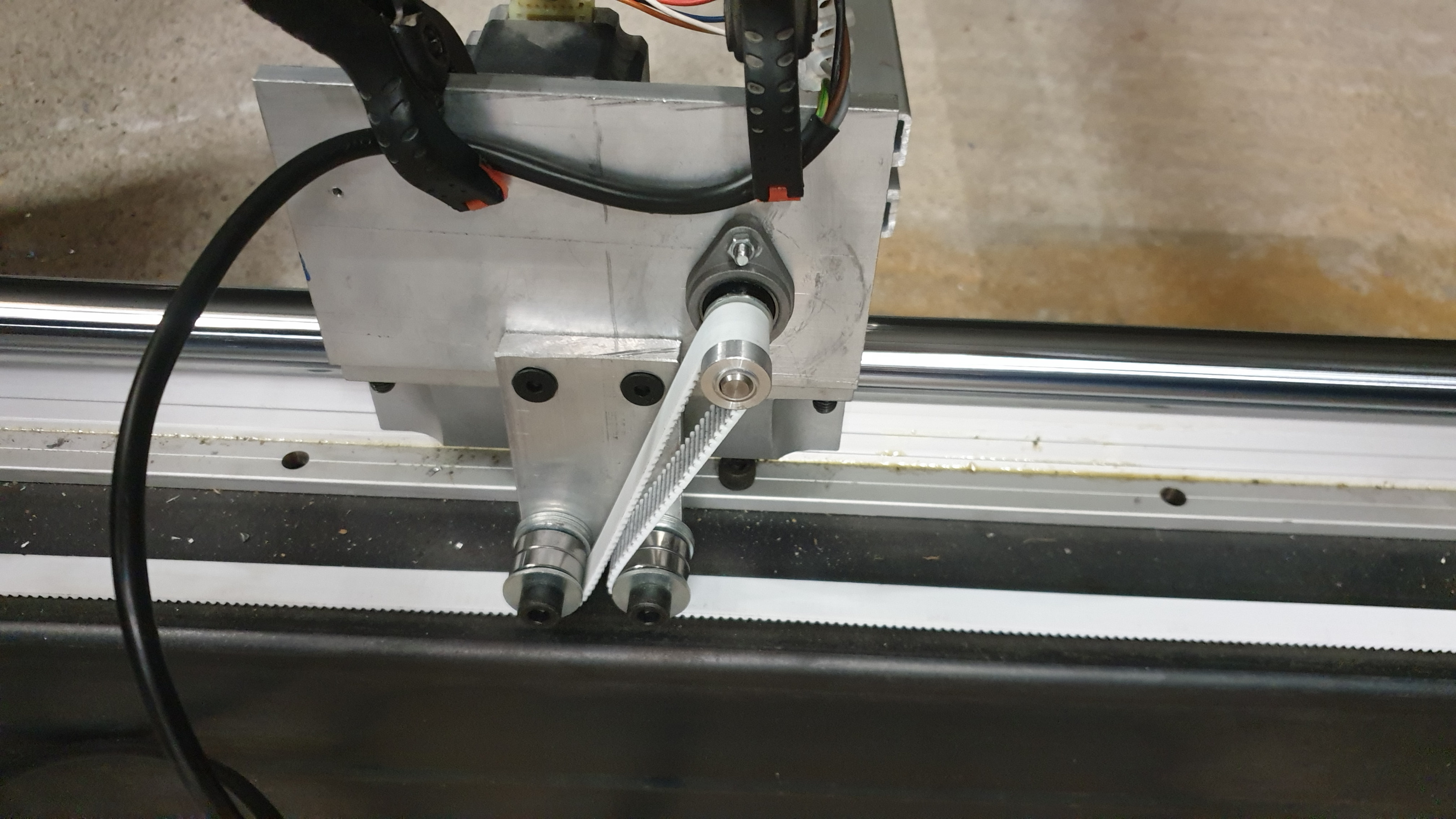

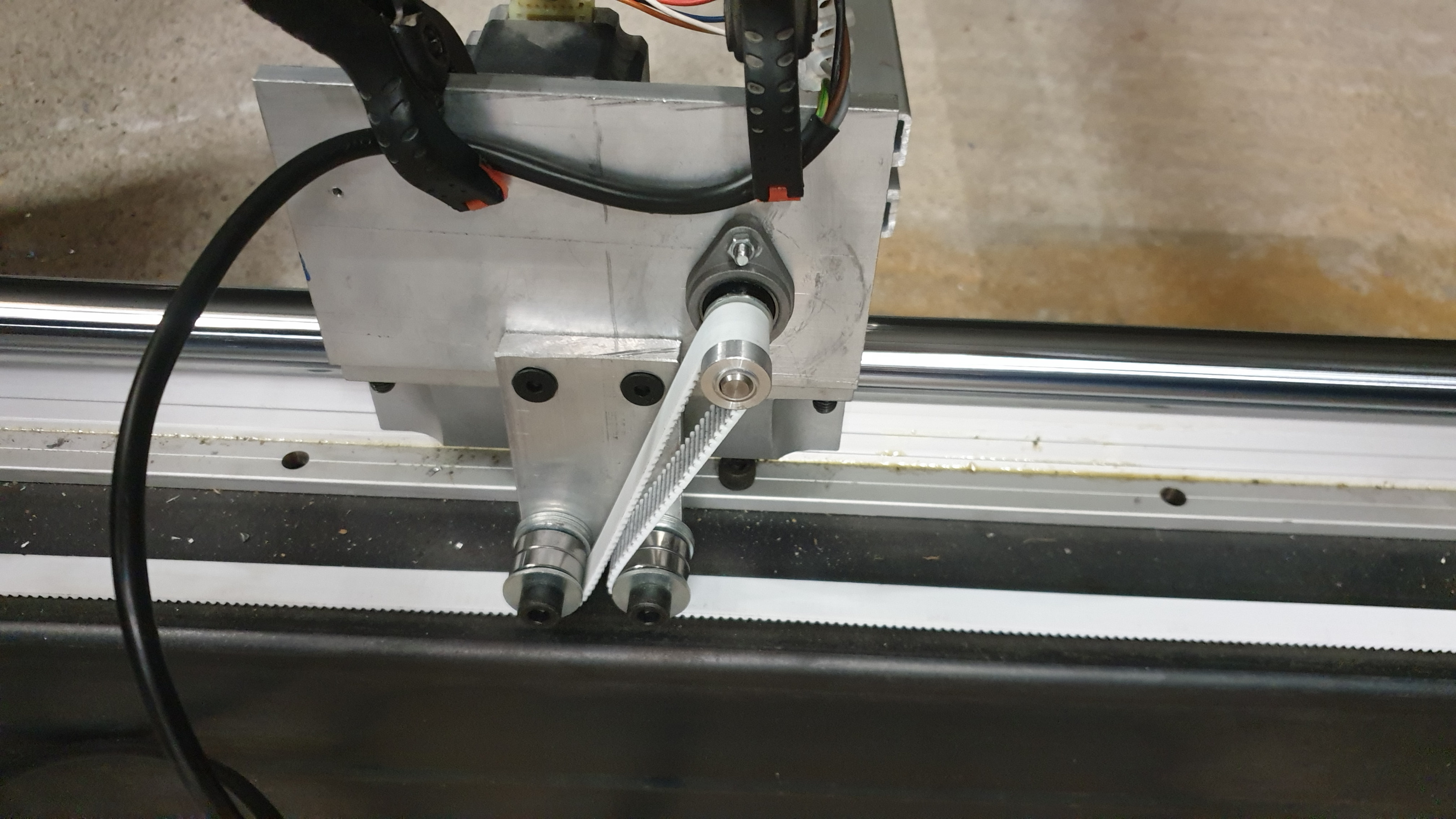

First up some photos of the setup to get things working, just to prove what I have made isn't going to be an epic fail.

Video time:

First up some photos of the setup to get things working, just to prove what I have made isn't going to be an epic fail.

Video time:

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

12 Sep 2021 08:38 #220282

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Just a short clip of rapids at 30m/min and acceleration of 3m/s/s. Obviously "real" plasma tables can do higher speeds but I'm impressed what these relatively small nema23's can do with this 3:1 gearing.

The following user(s) said Thank You: tommylight, Clive S, rodw, snowgoer540

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

12 Sep 2021 11:17 #220291

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Very nice and very glad you are happy !

Now back to work and stop jogging the poor thing all day long !

Now back to work and stop jogging the poor thing all day long !

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

12 Sep 2021 19:32 #220361

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

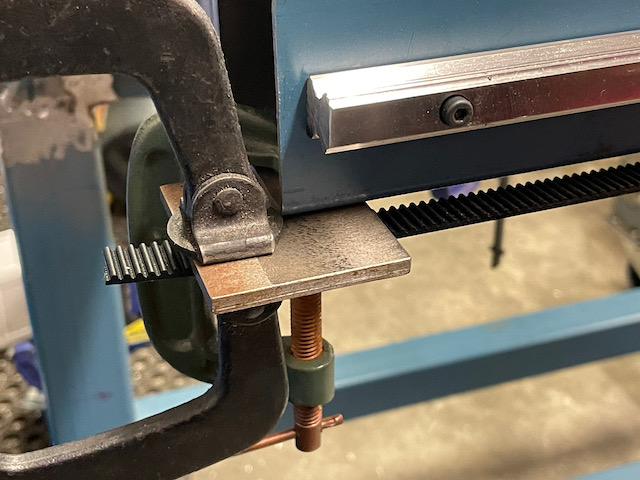

tommylight - ok, back to it! So, belt tensioning. I’m starting to think through how best to do this. As a result a couple of questions …

(1) how tight do you need to get the belts? Mine are steel reinforced, i couldn’t find fibreglass at the time I ordered. Plus how do you tell if you have the belt at the correct tension?

(2) what sort of belt locking and tensioning mechanism did you use? If your build logs contain a pic just say and I will go looking again. I just can’t recall seeing any on this aspect of things.

cheers - J.

(1) how tight do you need to get the belts? Mine are steel reinforced, i couldn’t find fibreglass at the time I ordered. Plus how do you tell if you have the belt at the correct tension?

(2) what sort of belt locking and tensioning mechanism did you use? If your build logs contain a pic just say and I will go looking again. I just can’t recall seeing any on this aspect of things.

cheers - J.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

12 Sep 2021 21:36 #220370

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

1- if they spring back like guitar wire = they are to tight!

Have the machine running back and forth some 50mm and watch the straight parts of the belt, if the line they are moving at moves, tighten some more.

Not easy to explain, it is something requiring practice. Seen people braking them or bending the motor shaft ....

2- usually an M8 screw+ 2x 608 bearings+ 2 wide washers+ 2 nuts = all this mounted in a short slot between the motor and the big pulley. On long runs i do not use tighteners as the flex on the belt is enough to keep them in check.

Have the machine running back and forth some 50mm and watch the straight parts of the belt, if the line they are moving at moves, tighten some more.

Not easy to explain, it is something requiring practice. Seen people braking them or bending the motor shaft ....

2- usually an M8 screw+ 2x 608 bearings+ 2 wide washers+ 2 nuts = all this mounted in a short slot between the motor and the big pulley. On long runs i do not use tighteners as the flex on the belt is enough to keep them in check.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

12 Sep 2021 22:59 #220378

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Thanks. Think I understand the guitar part. Re the "watch the straight parts of the belt" what I am taking from this is if that flat part of the belt is shift and/or the teeth on it are moving back and forth from a witness mark then you probably have excessive slack such that there is too much backlash in the system.

Re the tensioner I had a look at one of your builds again as I was trying to visualise what you are getting at. Pic below from your 2+2 thread.

Do you mean that one of the idler is in a slot and that after getting the base tension in place when clamping the ends you shift that to tune it in?

Thanks - J.

Re the tensioner I had a look at one of your builds again as I was trying to visualise what you are getting at. Pic below from your 2+2 thread.

Do you mean that one of the idler is in a slot and that after getting the base tension in place when clamping the ends you shift that to tune it in?

Thanks - J.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

12 Sep 2021 23:57 #220380

by tommylight

Replied by tommylight on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

Yes and yes, both idlers have a small slot as the space for them is very limited.

Please Log in or Create an account to join the conversation.

- Joco

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

13 Sep 2021 22:31 #220520

by Joco

Replied by Joco on topic "Origami" CNC Plasma Build - folding 1200 x 600mm cut area

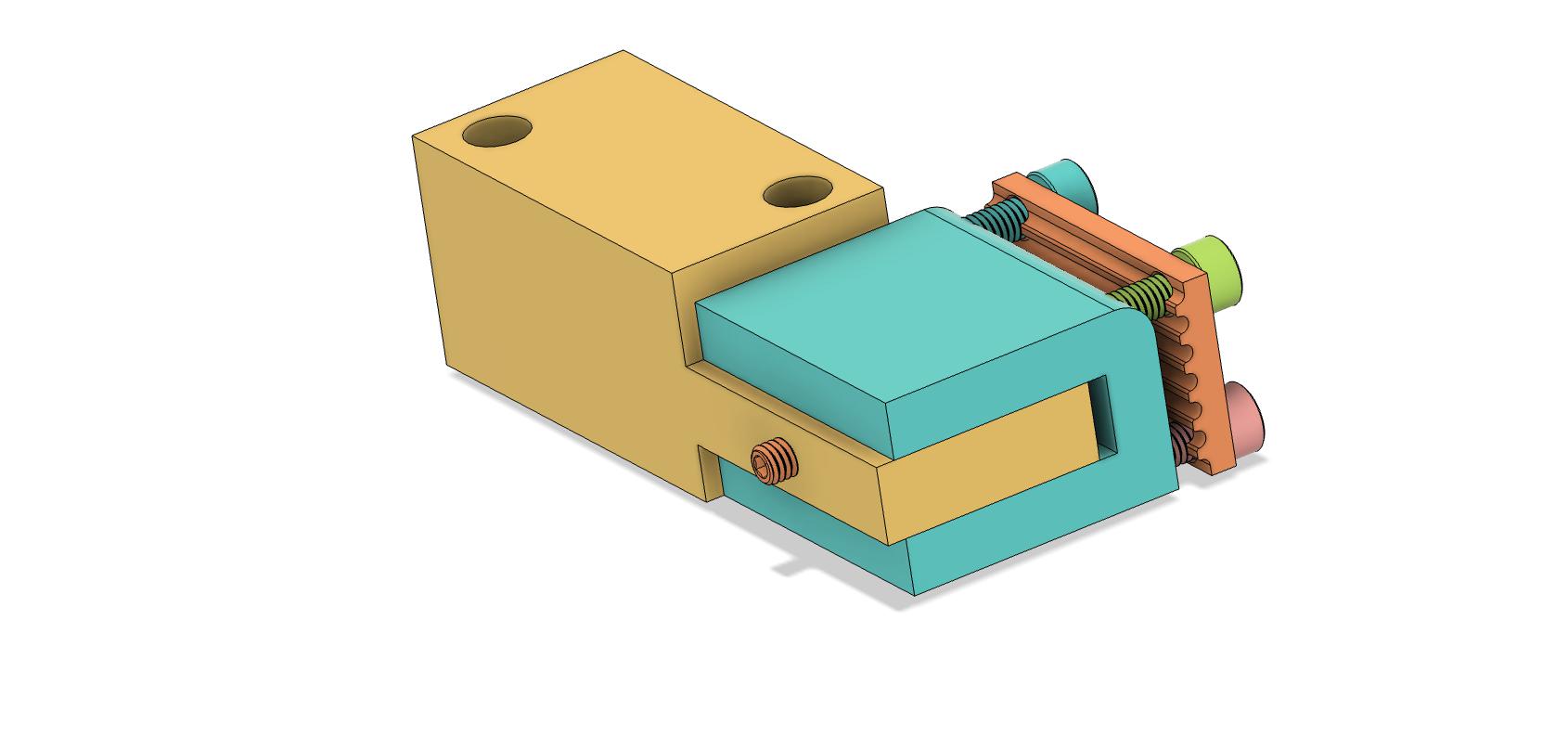

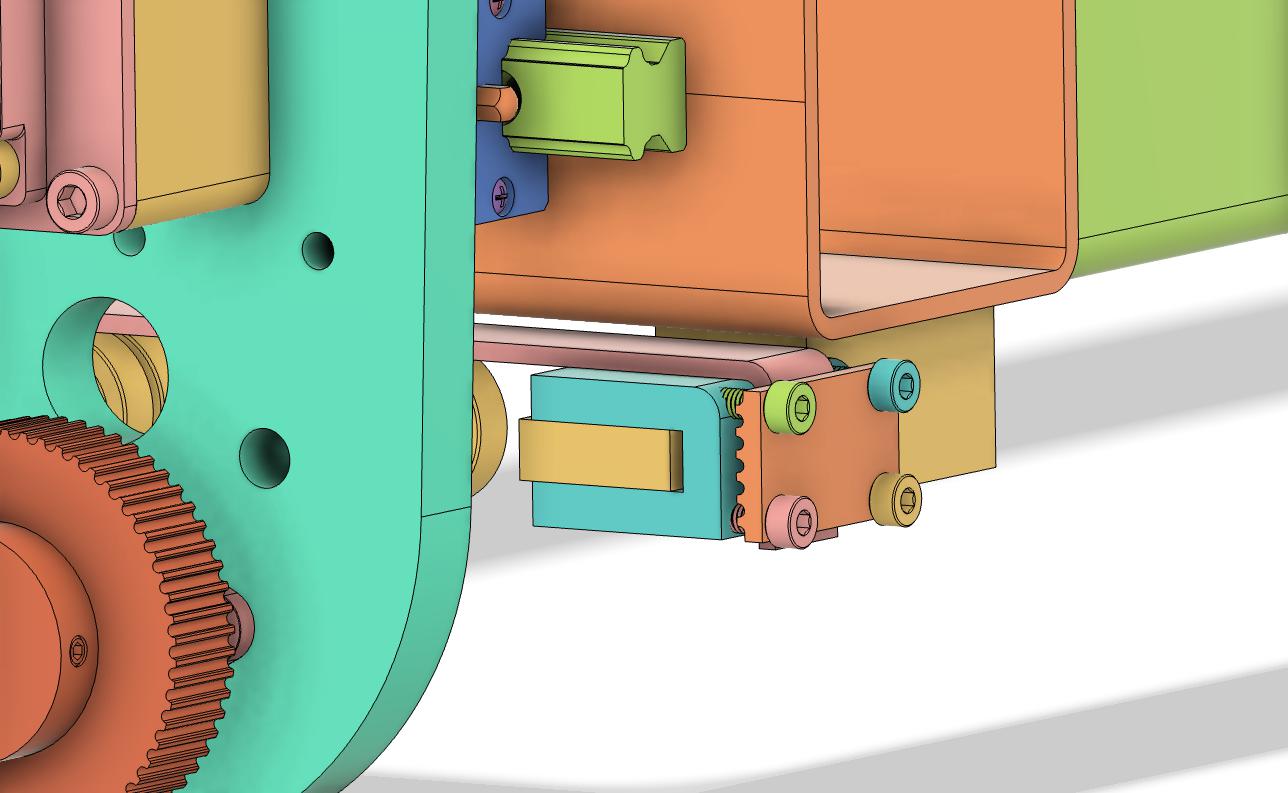

Working on belt tensioner system. I looked into following tommyligts pattern and while possibly doable its going to be very tight and if I get it wrong it will be a little destructive on the gantry side plates. So for now I am going to try something along these lines.

Tensioner assembly drawing. This will be mounted under the end of the table frame.

Shown in context of the overall assembly at the end/edge of the table top with the gantry side shown in a homed position. I might end up using this end as a fixed mounting point and put the adjustable end (the one shown) at the other end where this is a bit more room .

Not perfect but workable I think.

Tensioner assembly drawing. This will be mounted under the end of the table frame.

Shown in context of the overall assembly at the end/edge of the table top with the gantry side shown in a homed position. I might end up using this end as a fixed mounting point and put the adjustable end (the one shown) at the other end where this is a bit more room .

Not perfect but workable I think.

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.525 seconds